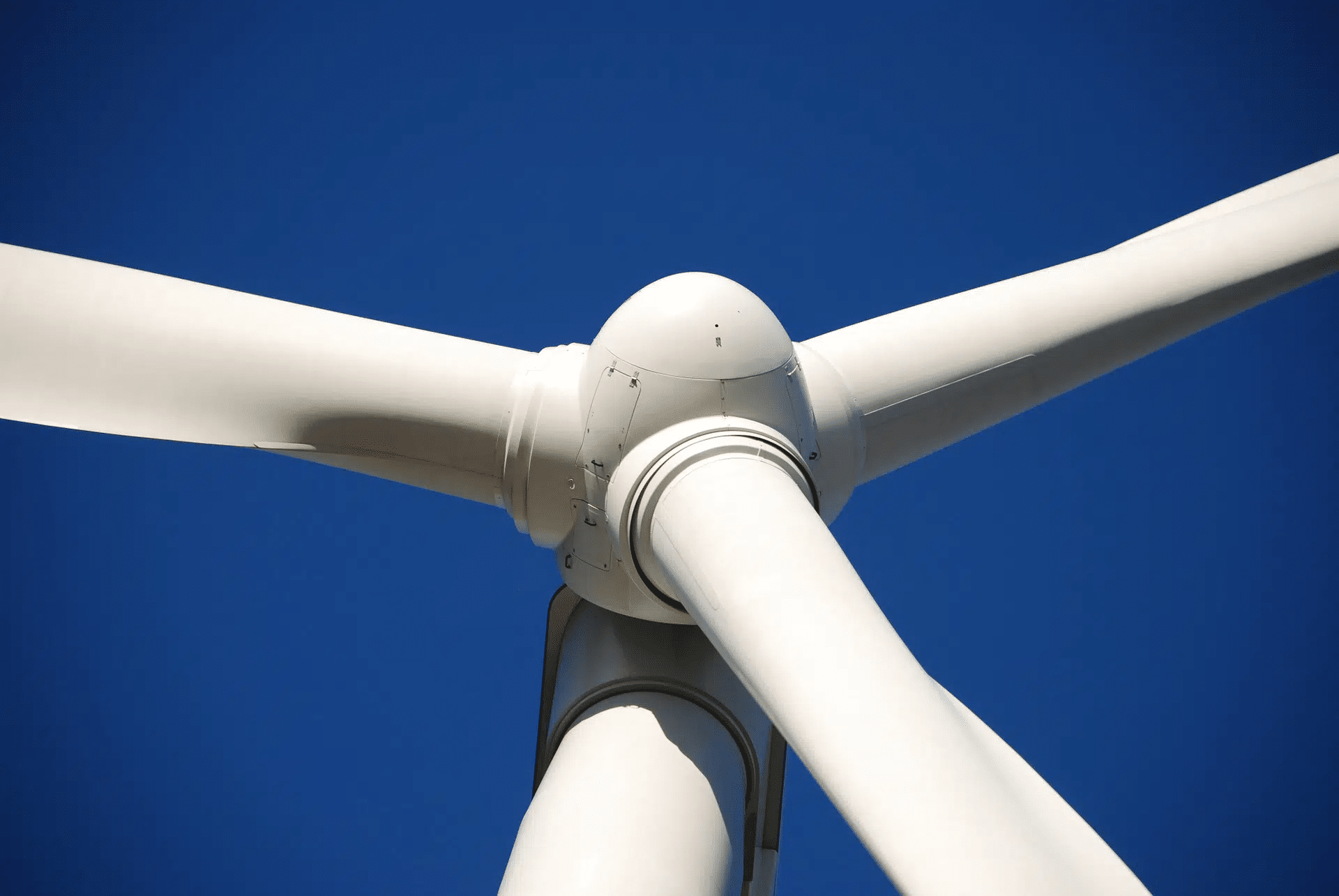

What if you could anticipate where the next failure in your network of assets is likely to occur? Or optimise your maintenance schedule for minimum downtime? You would save in cost, effort, and energy and gain customer satisfaction and performance. Alchemite™ machine learning can provide such valuable guidance, based on past and present data from your in-service assets.

In manufacturing, ongoing maintenance of equipment and production line machinery represents a major cost, where unplanned downtime costs an estimated $50 billion a year (according to a Solomon RAM study) and asset failure is the cause of 42% of this downtime. Predictive maintenance is being adopted by forward thinking manufacturers who understand that predicting equipment and process malfunctions can save considerable time and costs.

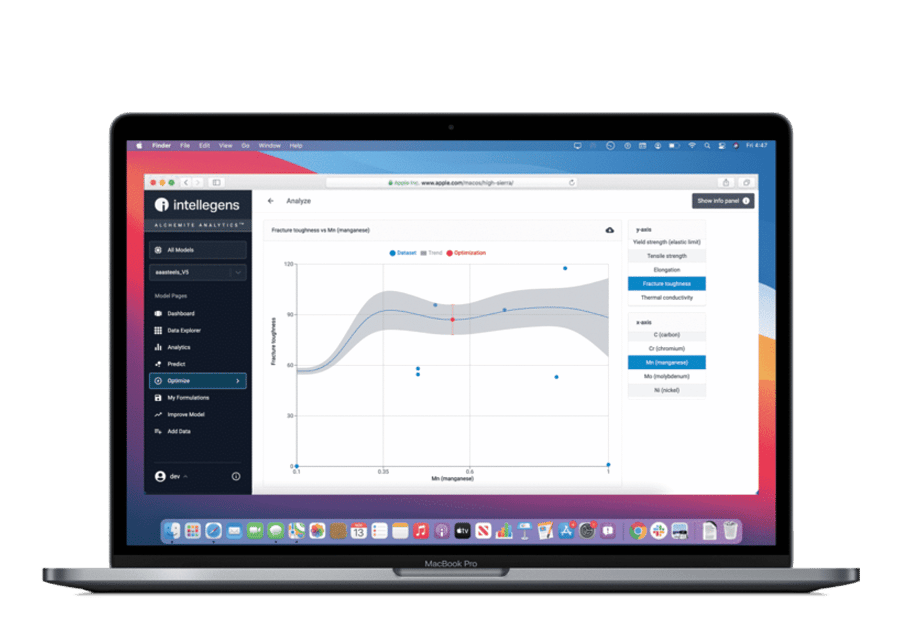

Adopting such methods to existing manufacturing processes is not straightforward. In order to make accurate predictions, there has to be existing data in place to guide the model. However, complete, clean datasets are rare. Intellegens has developed a machine learning tool, Alchemite™, that trains models on all available data, no matter how sparse or noisy. We use underlying correlations to accurately predict missing values and generate the most complete models possible.

Applying this novel method to the available historical and simulated data enables organisations to identify opportunities for reducing costs and downtime, time savings, and overall performance improvements, through predictive maintenance and process optimisation.

Alchemite™ for predictive maintenance

- Auto-generate and refine models to understand the performance and likely failure of assets

- Quantify the uncertainty of predictions to enable rational risk assessment

- Understand where more data is needed on your network of assets

- Model asset behaviour to prioritise maintenance work for maximum efficiency and minimum downtime