Hands up if you ever owned a Microsoft Zune. Didn’t think so. The MP3 player is one of Microsoft’s few failures partly because, by the time it was released, Apple had cornered the market. Time-to-market is critical.

This is hardly a new idea. It has driven global trade for thousands of years. It’s 30 years since a classic McKinsey study showed that companies lose 33% of after-tax profit when products ship six months late. Of course, lots of factors feed into time-to-market: marketing strategy, distribution, supply chains, production processes. The McKinsey study was part of a wave of interest in ‘just in time’ approaches, driven by the success of 1970s Japanese manufacturing. Here, we’re most interested in the earliest part of the value chain: R&D. A 2015 Boston Consulting Group report found fast innovators not only gain first-mover advantages, they also lower development costs, increase market share, and improve forecasting accuracy for their businesses.

R&D is a race. In materials, chemicals, and manufacturing, it’s one where there is plenty of scope for smart companies to get ahead. In a recent webinar, Dr Richard Padbury of Lucideon cited another McKinsey report that found average development times of 20 years for a new material. Of course, our real interest is in how machine learning (ML) can change this picture. Here are three areas to look at.

1. Do fewer experiments

As discussed in a previous blog, ML can help to focus experimental programs which are, for many products, still the largest time-sink in development. It can do this by helping to select the set of experiments that most efficiently explore potential solutions – continually answering the question ‘what experiment should I do next?’ At Intellegens, we aim for reductions of 50-90% in experimental workload when we apply our ML method to such challenges. To succeed, these ML methods need to be able to extract insights from the existing experimental data, even when that data is sparse and noisy. They also need to accurately quantify the probability of success for a particular experimental route, enabling rational decision-making, even where available data is limited.

2. Increase the probability of breakthrough insights

Often real speed-ups in R&D come from breakthrough insights – moments of inspiration, or the coming-together of key pieces of information. You can never guarantee these breakthroughs, but you can increase their probability. ML can be invaluable here, exploring large, multi-dimensional datasets and finding correlations that a human may never spot. We saw an interesting example recently with the publication of a paper on the search for anti-malarial drugs. ML found a promising candidate compound that chemists admitted they would have dismissed as “ill advised”. The compound was subsequently synthesised and its potency was experimentally validated.

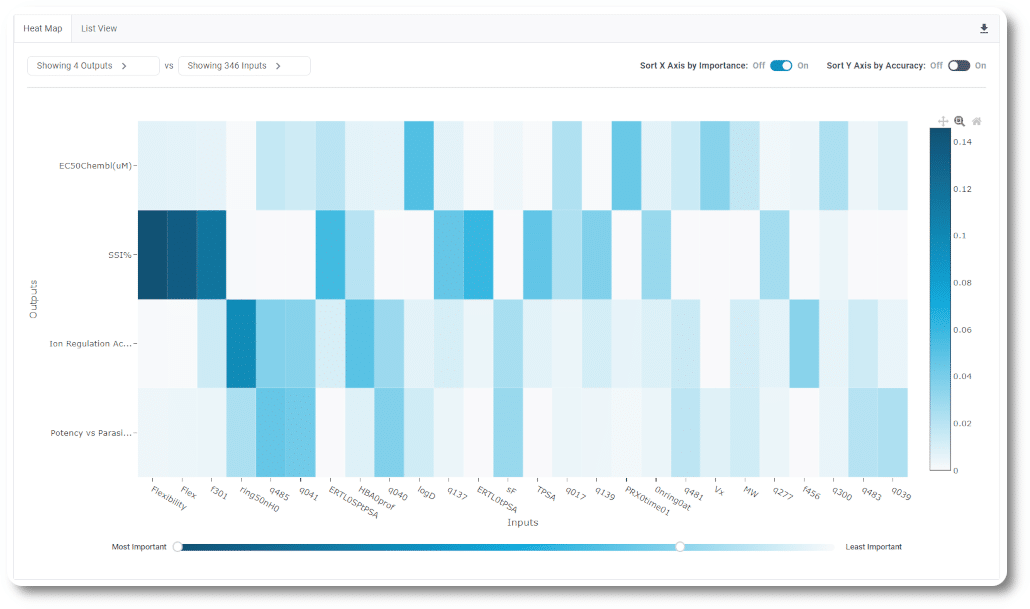

It’s also important, though, to focus on that word ‘insight’. It’s not enough to just run an algorithm and predict an outcome – you need understanding of why the prediction comes out that way. Analytics such as the importance chart (pictured) help. This shows which inputs to a system drive which outputs.

3. Re-use existing knowledge

“We would be so much faster if only we knew what we already know”. There is rightly a lot of focus in industry on IT systems that capture legacy data and its inter-relationships. For chemical, materials, and biological systems, examples may include results from experiment and analysis, outputs of computer simulations, and process data. From further downstream there may be (for pharmaceuticals) data from clinical trials or patient data, or (for manufactured products) manufacturing or in-service data. Again, ML can be applied to exploit these data resources. But, again, the data sparsity challenge appears, since data collated from multiple sources will inevitably have gaps and inconsistencies. You will need ML methods that can cope.

Once an ML model has been built, it can itself become a useful way to capture insights and knowledge for later re-use. But this is difficult where running or modifying the models requires coding or scripting knowledge or data science expertise. We find that many of our customers want to be able to deploy the results of ML studies to their scientists and engineers via an accessible platform technology, such as Alchemite™ with its web user interface.

Maybe you need to try something new?

If R&D is a race then, as in any race, you’ll probably have to do something different to get ahead. Machine learning could be that difference. Maybe you tried it before and didn’t get too far. That might be due to some of the hurdles we’ve covered here – sparse, noisy data, the need for uncertainty quantification, lack of effective analytics, or the difficulty of deploying useful models. If so, perhaps it’s worth taking another look at how these challenges are being overcome before your competition starts to gain ground?