Published in ‘Additive Manufacturing’

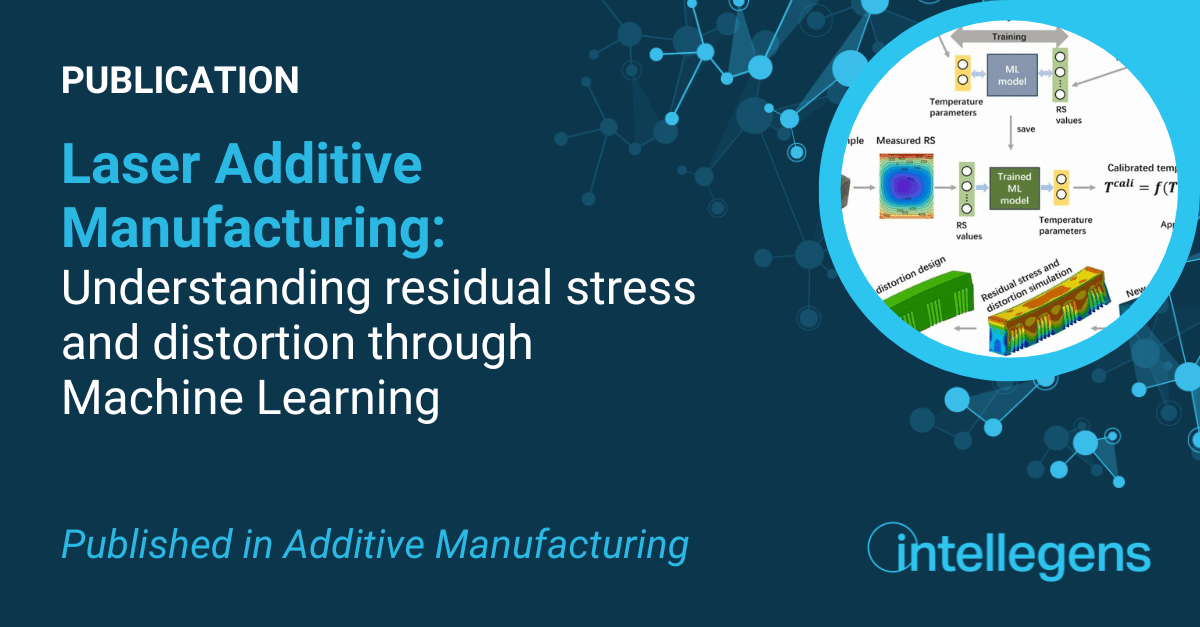

Intellegens scientist Joel Strickland is a co-author on a new paper that applies machine learning to support a robust tool for predicting residual stresses and mitigating distortion in Laser Powder Bed Fusion (LBPF) processes. These are key factors in optimising design and manufacturing practices for this Additive Manufacturing technology.

Abstract

This study presents a methodology for simulating residual stress and distortion in Laser Powder Bed Fusion (LPBF) additive manufacturing by integrating a simplified finite element modelling (FEM) framework, high-resolution residual stress mapping via the contour method, and machine learning (ML) algorithms to enhance both simulation efficiency and accuracy. Using a two-parameter temperature field, the FEM model reduces computational complexity while maintaining precision. Three ML models – multi-layer perceptron (MLP), gradient boosting regressor (GBR), and random forest regressor (RF) – are trained on FEM simulation data and validated against experimental measurements, showing effective performance with discrepancies ranging from 52 MPa to 84 MPa. The methodology also enables accurate distortion predictions, allowing for a key application on distortion mitigation, where predicted distortions are inversely applied to the CAD model to counteract stress-induced warping. This approach reduces distortion in a bridge sample from 0.94 mm to 0.06 mm – a 94% improvement. This integrated approach provides a robust tool for predicting residual stresses and mitigating distortions in LPBF, optimizing design and manufacturing practices.