Every business has vital processes that it needs to optimise and control. These could be physical processes, such as chemical or materials production or discrete manufacturing. Or they could be business processes, such as supply chain management or logistics. You want to maximise and maintain the quality of outputs while minimising the cost and effort input. And you are often trying to achieve these goals using incomplete, sparse, or noisy data.

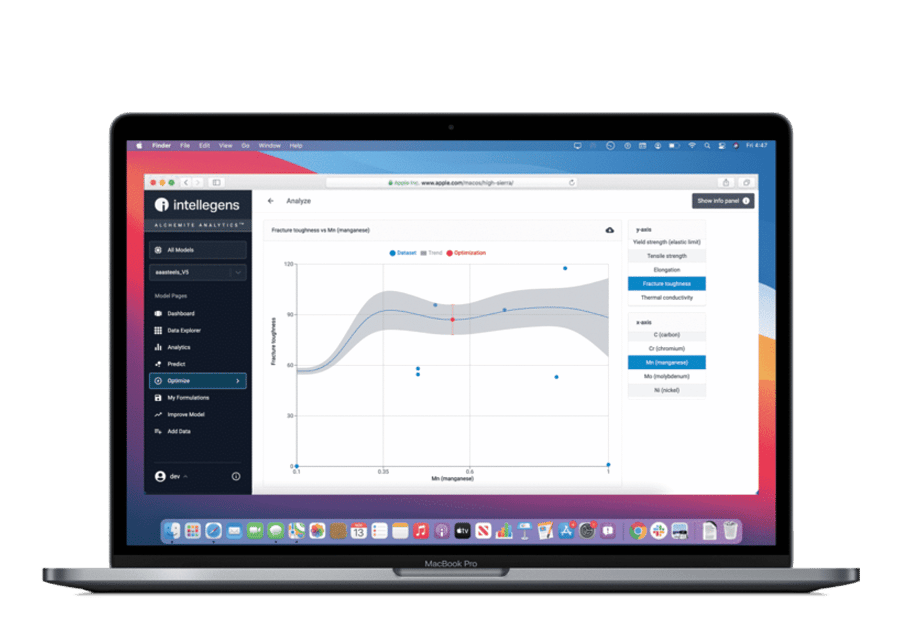

Alchemite™ extracts maximum value from such data. Originally designed for complex scientific problems, it can be applied to any numerical dataset. Example uses include selecting process inputs to deliver the optimal combination of outputs based on historical data, monitoring inputs and outputs in order to recognise outliers and maintain quality, and understanding and managing risk in your processes.

Applied machine learning

The Alchemite™ machine learning software can build a model based on past and current process data, which can then be used predictively to:

Understand your processes. Find out which process parameters correlate most strongly with the target properties that your process aims to deliver, and how changes in these parameters impact the outputs.

Design optimised processes. Use the underlying correlations in your manufacturing data to predict process parameters most likely to deliver the outcomes that you want.

Reduce cost. Run virtual experiments to reduce the number of physical tests and prototypes required, while finding options that lower energy requirements and minimise wasted material.

Case studies

AMRC – Composite manufacturing

Alchemite™ was applied at the AMRC to understand manufacturing processes for an important class of composite material used in the aerospace and automotive sectors. It accurately predicted a key failure mechanism based on data from 80% fewer tests than are typically required, understanding the impact of factors such as tool geometry and material selection. Such understanding can inform design of experimental campaigns to remove unnecessary tests, cut direct costs, and reduce material wastage.

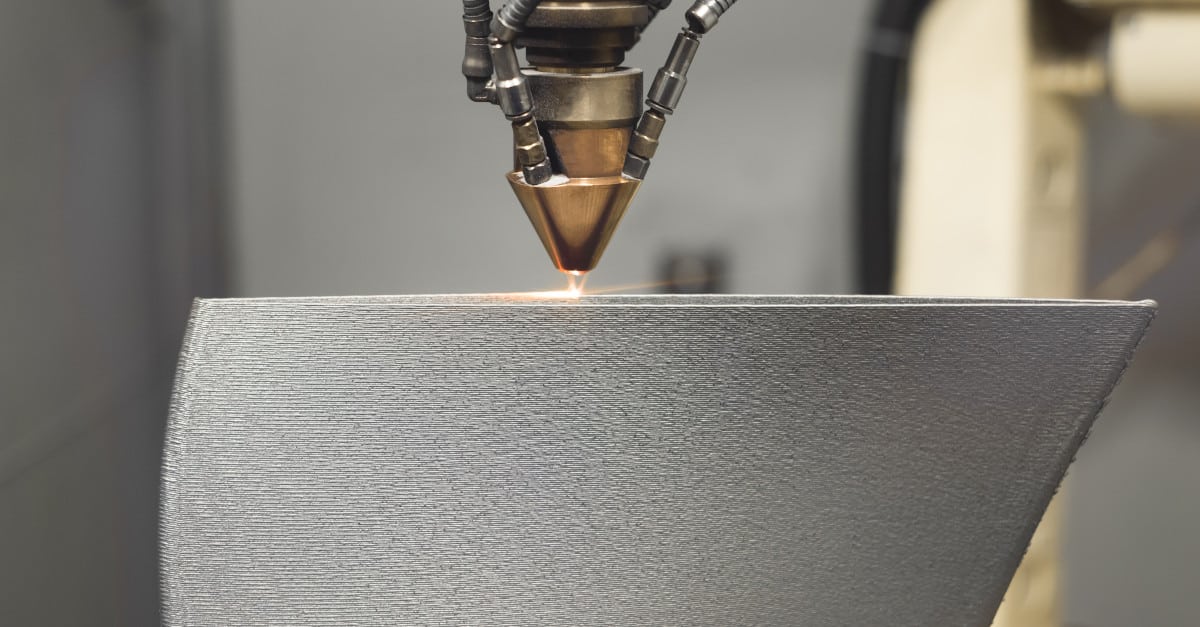

Project MEDAL – AM process parameters

Machine learning can make the additive manufacturing (AM) process for metallic alloys in aerospace cheaper and faster, supporting the production of lightweight, fuel-efficient aircraft. In collaboration with the University of Sheffield Advanced Manufacturing Research Centre (AMRC) and Boeing, Intellegens applied the Alchemite™ machine learning software to design new AM parameter sets for laser powder bed fusion (LPBF) and test them for nickel base alloys across two experimental cycles.

Other resources

Recorded webinar – AI for high-speed digital manufacturing

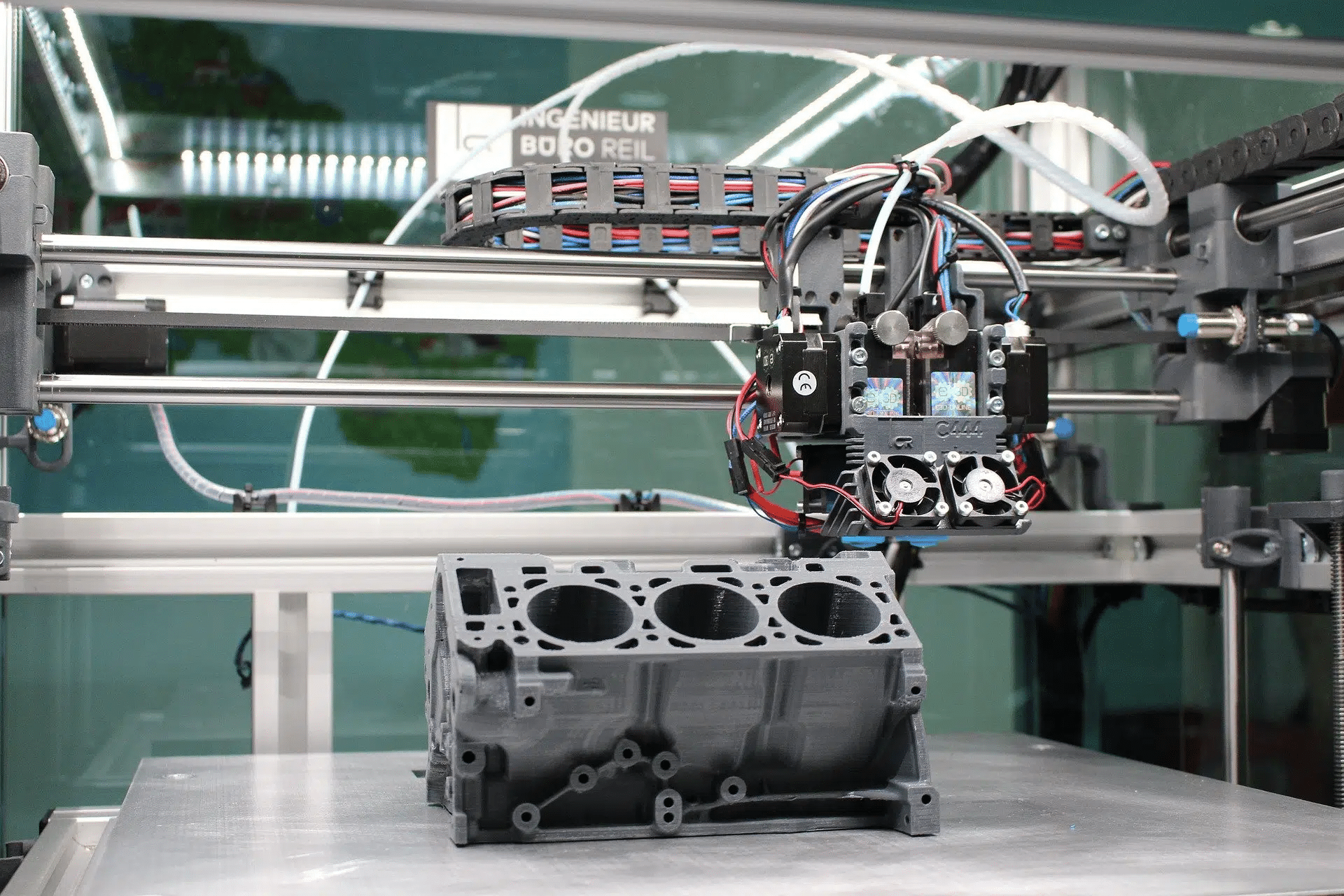

Find out how Alchemite™ machine learning is being applied by 3D Printing innovator Photocentric to optimise large-scale, high speed digital manufacturing processes. The project aims to enable an autonomous manufacturing process.

Blog – embedding machine learning in products and processes

We discuss how machine learning is impacting manufacturing and process industries beyond the lab, with examples of machine learning for process control, on-device applications, and machine learning as a customer service tool supporting customisation of formulated products.

Alchemite™ for process optimisation and control

- Analyse data to identify outliers, even for sparse, noisy data

- Quantify uncertainty to focus process improvements on routes most likely to succeed

- Understand where more data is needed on your production processes

- Design optimal process parameters to improve quality, energy efficiency, and performance

- Monitor production data to refine models and identify potential process changes