The goal of the neural network tool is to predict the composition and processing variables that are most likely to produce a material that fulfills the multi-criteria target specification.

The tool first constructs a predictive model for each property as a function of the composition, which for the Mo-base alloys presented in this paper comprises of the elements {Nb,Ti,C,Zr,Hf,W,Mo}.

The new proposed alloy has been experimentally verified to have properties that exceed other, commercially available Mo-basealloys.

Abstract

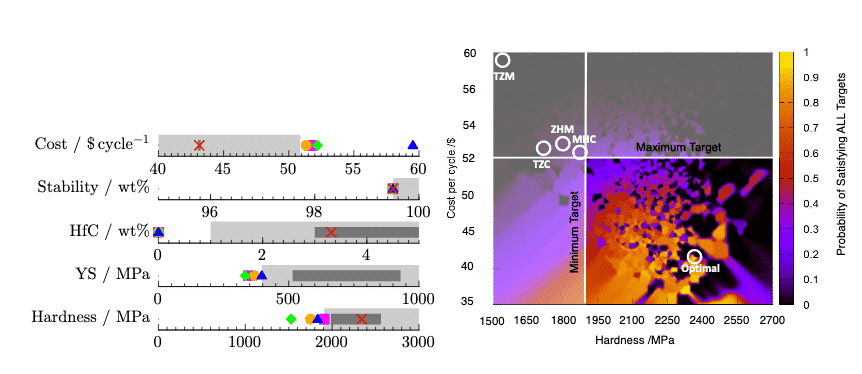

An artificial intelligence tool is exploited to discover and characterize a new molybdenum-base alloy that is the most likely to simultaneously satisfy targets of cost, phase stability, precipitate content, yield stress, and hardness. Experimental testing demonstrates that the proposed alloy fulfills the computational predictions, and furthermore the physical properties exceed those of other commercially available Mo-base alloys for forging-die applications.

The first section of this paper outlines the artificial intelligence tool and specifies the chosen targets for the relevant material properties: cost, phasestability, HfC content, yield stress, and hardness. In the second section, the tool is used to propose the new Mo-base alloy that is most likely to exceed the design targets. The final section presents experimental results for the phase stability, HfC content, and hardness to verify the model predictions and demonstrate that the alloy has properties that surpass those of other commercially available Mo-base forging die alloys.

Publication details

Publication: Scripta Materialia

Title: Probabilistic design of a molybdenum-base alloy using a neural network

Authors: B.D.Conduit, N.G.Jones, H.J.Stone, G.J.Conduit

DOI / Link: https://doi.org/10.1016/j.scriptamat.2017.11.008