Peer-reviewed Paper

A neural network tool was used to discover a new nickel-base alloy for direct laser deposition most likely to satisfy targets of processability, cost, density, phase stability, creep resistance, oxidation, fatigue life, and resistance to thermal stresses. A neural network tool was used to discover a new nickel-base alloy for direct laser deposition.

Abstract

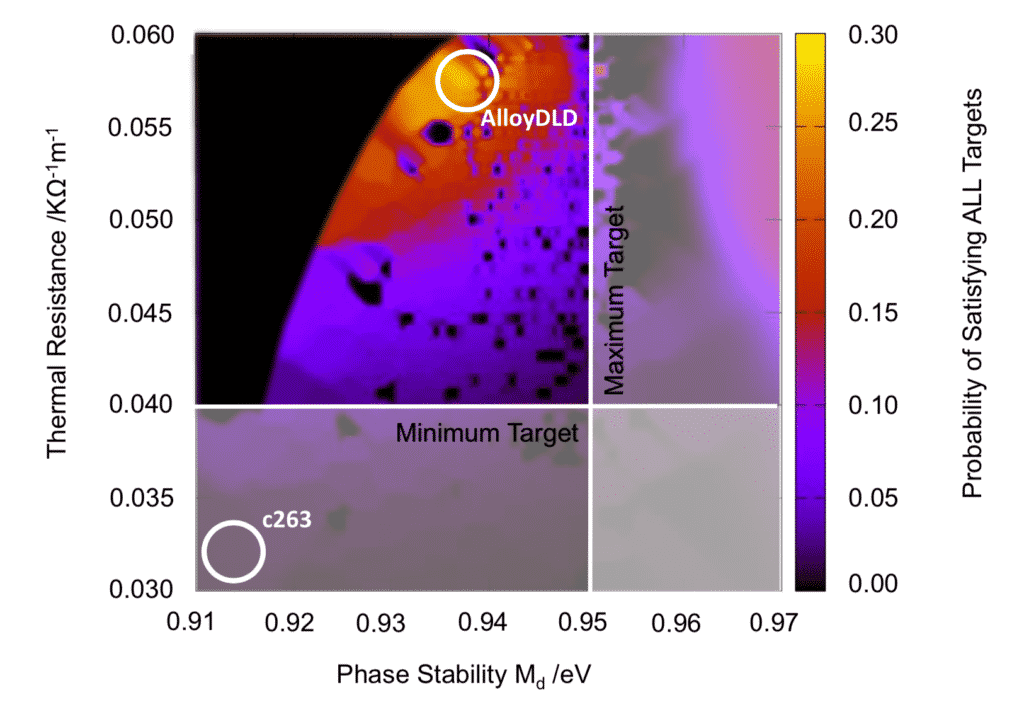

A neural network tool was used to discover a new nickel-base alloy for direct laser deposition most likely to satisfy targets of processability, cost, density, phase stability, creep resistance, oxidation, fatigue life, and resistance to thermal stresses. The neural network tool can learn property-property relationships, which allows it to use a large database of thermal resistance measurements to guide the extrapolation of just ten data entries of alloy processability. The tool was used to propose a new alloy, and experimental testing confirms that the physical properties of the proposed alloy are better tailored to the target application than other available commercial alloys.

Publication details

Publication: Materials & Design

Title: Probabilistic neural network identification of an alloy for direct laser deposition

Authors: B.D.Conduit, T.Illston, S.Baker. D.Vadegadde Duggappa, S.Harding. H.J.Stone, G.J.Conduit

DOI / Link: https://doi.org/10.1016/j.matdes.2019.107644